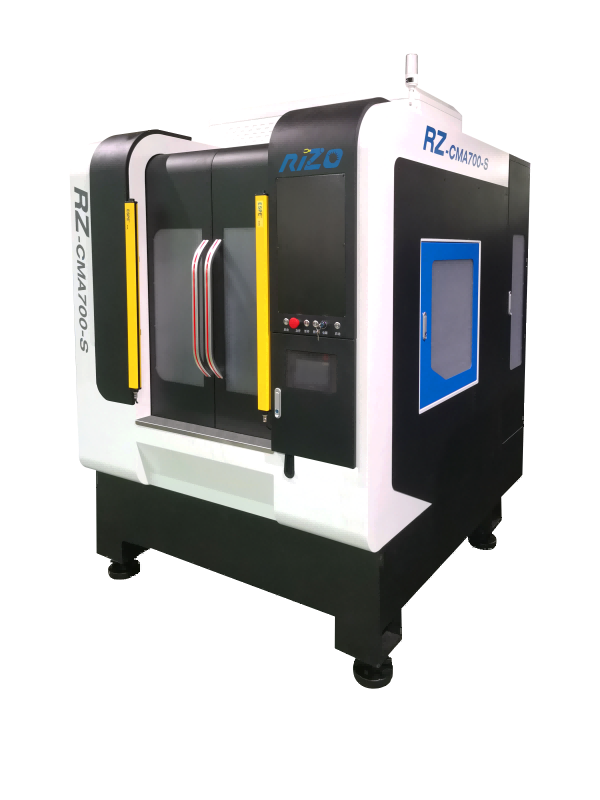

6 Axis CNC Deburring Machine

6 Axis CNC Deburring Machine

1.X, Y, Z, A, B, C 6-axis servo special CNC machine;

2.Adopting Taiwan Syntec system, optional RTCP function;

3.Adopting mature RRLLL configuration double-swing table structure;

4.Supporting establishing workpiece coordinate system, convenient & quick programming;

5.Adopting Yaskawa servo motor, ensuring quick mechanism responding speed anddistortionless corner trajectory;

6.Cradle, worktable or cutter shaft enabling rotating or swinging, working in an optimal posture, improving working efficiency;

7.Main structure adopting iron casting with high rigidity, precision and stability, supporting high-speed feeding, no knife vibration;

8.4 tools rotating and switching quickly, no need to go back and forth to the tool change position, saving tool change time;

9.Based on product cleaning requirements, various consumables can be installed, such as milling cutters, rotary files, grinding heads, wire brushes, files, gauze, etc.;

10.Worktable has positioning pin, and simple quick tooling replacement;

11.The system can store 1000 programs, which can be called when changing product, avoiding reprogramming;

12.The system can automatically compensate for the loss of consumables;

13.Compact equipment structure, small footprint, suitable for one person to operate multiple machines;

14.Whole machine sealed design, low pollution to workshop environment;

15.Suitable for working with die-casting machine to form automatic integrated production.

All rights reserved

All rights reserved